The D-SIMCON Forecaster provides visibility into critical KPIs such wafer arrivals, wafer moves and WIP down to the work centre and product group level with a time horizon of up to two weeks. Visibility into these forecasted KPIs allows production departments to evaluate various changes of fab settings to smoothen the WIP flow such as tool dedication modification, dispatch rule adaptation, backup tool activation, sampling rate adjustment, daily lot release sequence adjustment, change of Preventive Maintenance plans at bottleneck resources, i.e. measures that can be implemented fast enough to achieve the desired impact on the WIP flow within a time horizon as short as a few days. The D-SIMCON Forecaster comes with unique features such as

- High level of detail with many wafer-fab specific attributes that can be portrayed,

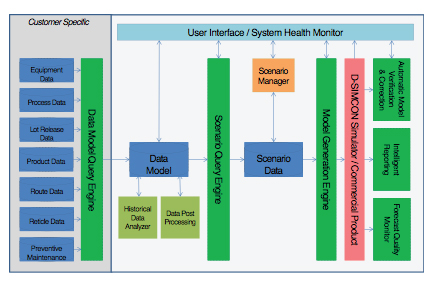

- Automated generation (<5 mins) of a dynamic, warm-started, high-fidelity simulation model comprising intelligent fusion of data from productive and planning data sources,

- Model maintenance features to calibrate and maintain the simulation model with high degree of automation:

- Determination of stochastic parameters (MTTF, MTTR, sampling rates),

- Resolution of data inconsistencies,

- Automatic Model Verification and Input Data Calibration,

- Automatic Model Validation.

- Unified Reporting Platform for both Performance Monitoring and KPI Forecasting,

- High execution speed and possibility to farm our replications and different scenarios on a parallel (Cloud) infrastructure → Analysis and optimisation 10-100 times faster compared to conventional simulation approaches.

Relevant Use Cases: Wafer Output Forecast, WIP Flow Forecast, Operator Resource Allocation, Engineering Lot Forecast, Tool Qualification and Dedication Adjustment, Preventive Maintenance Timing, Wafer Start Planning, Fab Incident Recovery