D-SIMCON is a suite of advanced domain-specific decision support products for WIP Management, Dispatching, Dynamic Capacity Planning and Load Mix Optimisation in Semiconductor Manufacturing. The solution addresses the typical challenges in operating and managing a dynamic production line:

• Unexpected material waves at work centres and breakdowns of bottleneck tools that create congestion and increase variability, resulting in frequent fire fighting;

• Challenges associated with ad-hoc solutions to address material flow congestion that tend to just push the problem to elsewhere in the fab;

• The difficulty of fine-tuning dispatch rules as their effect on the overall fab performance is hard to assess and could even be counterproductive;

• Painful and lengthy simulation model development processes limiting the usefulness of such simulation models;

• Missing data and/or bad data quality, leading to “Garbage-in –garbage-out” situations for the enabling decision support software modules, resulting in frustrations with their users;

• Challenges associated with quantifying customer order commitments and due-dates when using static capacity models for planning and managing customer orders.

All modules can be deployed on parallel computing infrastructure to minimise execution times and are hosted on a web server allowing centralised maintenance.

Overview

Concept

D-SIMCON is a simulation-based software suite for high-fidelity decision making in semiconductor manufacturing.

D-SIMCON comprises an advanced, multi-threaded simulation engine and a visual interface to model semiconductor specific features. It is pre-customised to the typical requirements of a wafer fabrication facility and simple to use.

D-SIMCON comes built in with an optimisation engine and the entire suite can be run on D-SIMLAB’s High-Performance Simulation Infrastructure (D-SIMClus), allowing simulation analysis and optimisation tasks to be carried out up to 100 times faster compared to conventional approaches. As a result, the benefits of simulation technology can be realised not only to address strategic and tactical issues but also for day-to-day operations decision making!

Enabling Technology

D-SIMCON is a simulation-based software suite for high-fidelity decision making in Semiconductor Industry. It consists of:

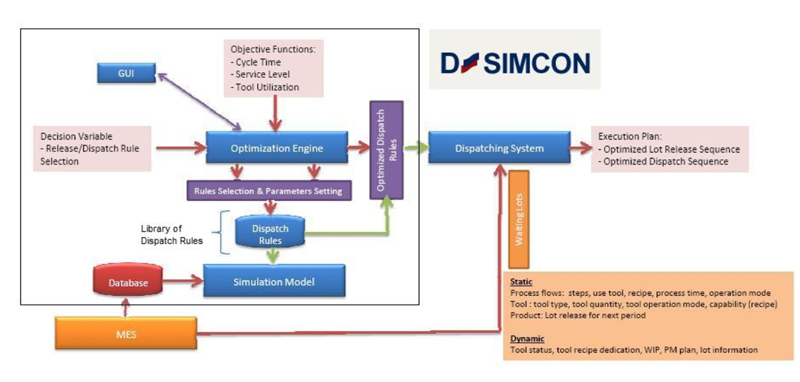

- A multi-threaded high-fidelity simulation model configured for Semiconductor Manufacturing

- An optimization engine to optimize critical parameters at a pre-defined interval. An example of parameters is dispatching rules e.g. give priority to lots that feed to bottleneck machine x, where x is a parameter.

- An integration module to link with operational systems (MES and Dispatching systems) to allow dynamic deployment of optimized parameters and dispatch rules on the production line

- A GUI to configure the decision variables for optimization, and trigger re-planning when unexpected event occurs

Benefits

D-SIMCON has been successfully applied with several major semiconductor manufacturers to generate measurable and sustainable savings. It is the core of D-SIMLAB’s solution offering for the Semiconductor Manufacturing industry. D-SIMCON can be used for:

- Analysis and prediction of the performance of a semiconductor manufacturing system through high-fidelity simulation of manufacturing operations

- Enhancement of semiconductor manufacturing operations through optimisation of operations management policies at critical resources

- Representation of multi-site manufacturing systems (Borderless Fab) and execution of the respective simulation in a distributed manner

Engagement

Commercial engagement mode for D-SIMCON suite of applications is based on the classical license model. An initial deployment project is carried out at the client site following which a license is purchased by the client. Annual maintenance fee entitles the clients to upgrades and there is no minimum engagement time.